Description

Welding electrodes are essential components in arc welding processes. They conduct electrical current to create an arc, which generates the heat needed to melt and fuse metals. Electrodes can be consumable (melt and become part of the weld) or non-consumable (do not melt, but may erode over time). The choice of electrode depends on the welding process, base material, and desired weld properties.

Types of Welding Electrodes:

1. Consumable Electrodes

– These electrodes melt during the welding process and become part of the weld joint.

– Commonly used in processes like Shielded Metal Arc Welding (SMAW) Gas Metal Arc Welding (GMAW/MIG) and Flux-Cored Arc Welding (FCAW)

Types of Consumable Electrodes

-Coated Electrodes (Stick Electrodes)

– Used in SMAW (Stick Welding).

– The coating (flux) provides shielding gas, stabilizes the arc, and improves weld quality.

– Examples: E6010, E7018 (common in structural steel welding).

– Bare Wire Electrodes

– Used in GMAW (MIG Welding).

– No flux coating; shielding gas is supplied externally.

– **Flux-Cored Electrodes

– Used in FCAW.

– Tubular wire filled with flux, which provides shielding and improves weld properties.

2. Non-Consumable Electrodes

– These electrodes do not melt during welding but may erode over time.

– Commonly used in processes like Gas Tungsten Arc Welding (GTAW/TIG) and Plasma Arc Welding (PAW)

Types of Non-Consumable Electrodes

– Tungsten Electrodes

– Used in GTAW (TIG Welding).

– Available in pure tungsten, thoriated, ceriated, lanthanated, and zirconiated varieties.

– Examples: EWTh-2 (2% thoriated tungsten), EWC (ceriated tungsten).

Electrode Classification:

1.Stick Electrodes (SMAW)

– Electrodes are classified by a standardized coding system (e.g., E6010, E7018).

– E Electrode.

– First Two Digits Tensile strength of the weld metal (e.g., 60 = 60,000 psi, 70 = 70,000 psi).

– Third Digit Welding position (1 = all positions, 2 = flat and horizontal).

– Fourth Digit Coating type and current type (e.g., 0 = cellulose sodium, 8 = low-hydrogen potassium).

2. Tungsten Electrodes (GTAW/TIG)

– Classified by their composition (e.g., pure tungsten, thoriated, ceriated).

– Color-coded for easy identification:

– Green: Pure tungsten.

– Red: Thoriated tungsten (2% thorium).

– Gray: Ceriated tungsten.

– Gold: Lanthanated tungsten.

Selection Criteria:

1. Base Material

– Match the electrode material to the base metal (e.g., mild steel, stainless steel, aluminum).

– Use low-hydrogen electrodes (e.g., E7018) for high-strength steels to prevent cracking.

2. Welding Process

– SMAW: Use coated stick electrodes.

– GMAW: Use bare wire electrodes.

– GTAW: Use tungsten electrodes.

3. Welding Position

– Some electrodes are designed for specific positions (e.g., E6010 for vertical and overhead welding).

4. Current Type

– Electrodes are designed for AC, DC+, or DC- current. Check the manufacturer’s specifications.

5. Joint Design and Thickness

– Thicker materials may require larger-diameter electrodes or specific types (e.g., E6010 for deep penetration).

6. Environmental Conditions

– Use electrodes with low-hydrogen coatings in humid or wet conditions to prevent hydrogen-induced cracking.

Common Electrodes and Their Uses:

1. E6010

– Deep penetration, all-position welding.

– Used for pipe welding and structural steel.

2. E6011

– Similar to E6010 but works on AC current.

– Used for general-purpose welding

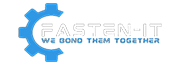

3. E6013

– Easy to use, smooth welds.

– Ideal for beginners and light-duty welding.

4. E7018

– Low-hydrogen electrode, high-strength welds.

– Used for structural steel and critical applications.

5. ER70S-6 (GMAW)

– Mild steel welding wire.

– Provides good weld appearance and spatter control.

6. EWTh-2 (TIG Tungsten)

– Thoriated tungsten electrode.

– Used for DC welding of steel, stainless steel, and titanium.

Storage and Handling

1. Moisture Control

– Store electrodes in a dry, temperature-controlled environment.

– Low-hydrogen electrodes (e.g., E7018) must be kept in an oven at 250°F (120°C) to prevent moisture absorption.

2. Avoid Contamination

– Keep electrodes clean and free from oil, grease, or dirt.

3. Check Expiry Dates

– Some electrodes have a limited shelf life, especially low-hydrogen types.