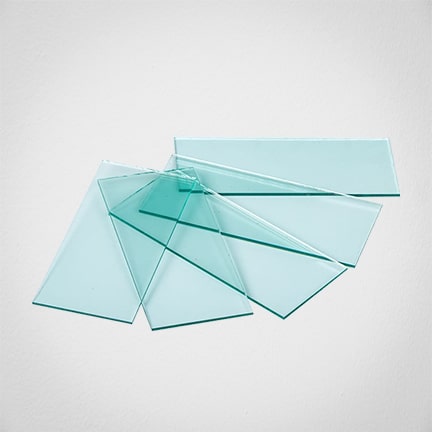

Description

Clear welding glass, often referred to as a **transparent welding lens** or **clear protective lens**, is a type of safety glass used in welding helmets or goggles. Unlike tinted welding glass, it is fully transparent and does not provide shading or filtering of intense light. Instead, it serves as a protective barrier against debris, sparks, and UV/IR radiation when used in conjunction with other protective layers or auto-darkening filters.

—

Key Features:

1. Transparency:

– The glass is completely clear, allowing for unobstructed vision when not actively welding.

– Often used as an outer cover lens to protect the primary filter (auto-darkening or fixed shade) from damage.

2. Protection

– Provides a physical barrier against sparks, spatter, and debris generated during welding.

– Blocks harmful UV and IR radiation when combined with an appropriate welding filter.

3. Material

– Made from durable materials such as polycarbonate or tempered glass, which are resistant to impact, heat, and scratches.

4. Compatibility

– Designed to fit most welding helmets, goggles, and hand shields.

– Often used as a replaceable cover lens to extend the life of the primary welding lens.

5.Durability

– Resistant to high temperatures and mechanical impacts, ensuring long-lasting performance in harsh welding environments

Applications:

1.Welding Helmets:

– Used as an outer cover lens to protect the auto-darkening or fixed shade lens from damage caused by sparks, spatter, or scratches.

– Easily replaceable when damaged or clouded, maintaining clear visibility.

2. Goggles and Face Shields:

– Provides clear vision while protecting the eyes from flying debris and radiation during grinding, cutting, or other preparatory work.

3.Industrial Safety

– Used in environments where eye protection is required without the need for light filtration.

Safety Considerations:

-Not for Direct Welding**: Clear welding glass alone does not provide adequate protection against the intense light generated during welding. It must be used in combination with a proper welding filter (auto-darkening or fixed shade).

– **Regular Inspection**: Check for scratches, cracks, or cloudiness, and replace the lens if damaged to ensure optimal protection and visibility.

– **Proper Fit**: Ensure the clear lens is securely installed in the helmet or goggles to prevent gaps that could allow debris or radiation to reach the eyes.

Maintenance

– Clean the lens regularly with a soft cloth and appropriate cleaning solutions to maintain clarity.

– Replace the lens when it becomes scratched, pitted, or cloudy to ensure clear vision and effective protection.