Description

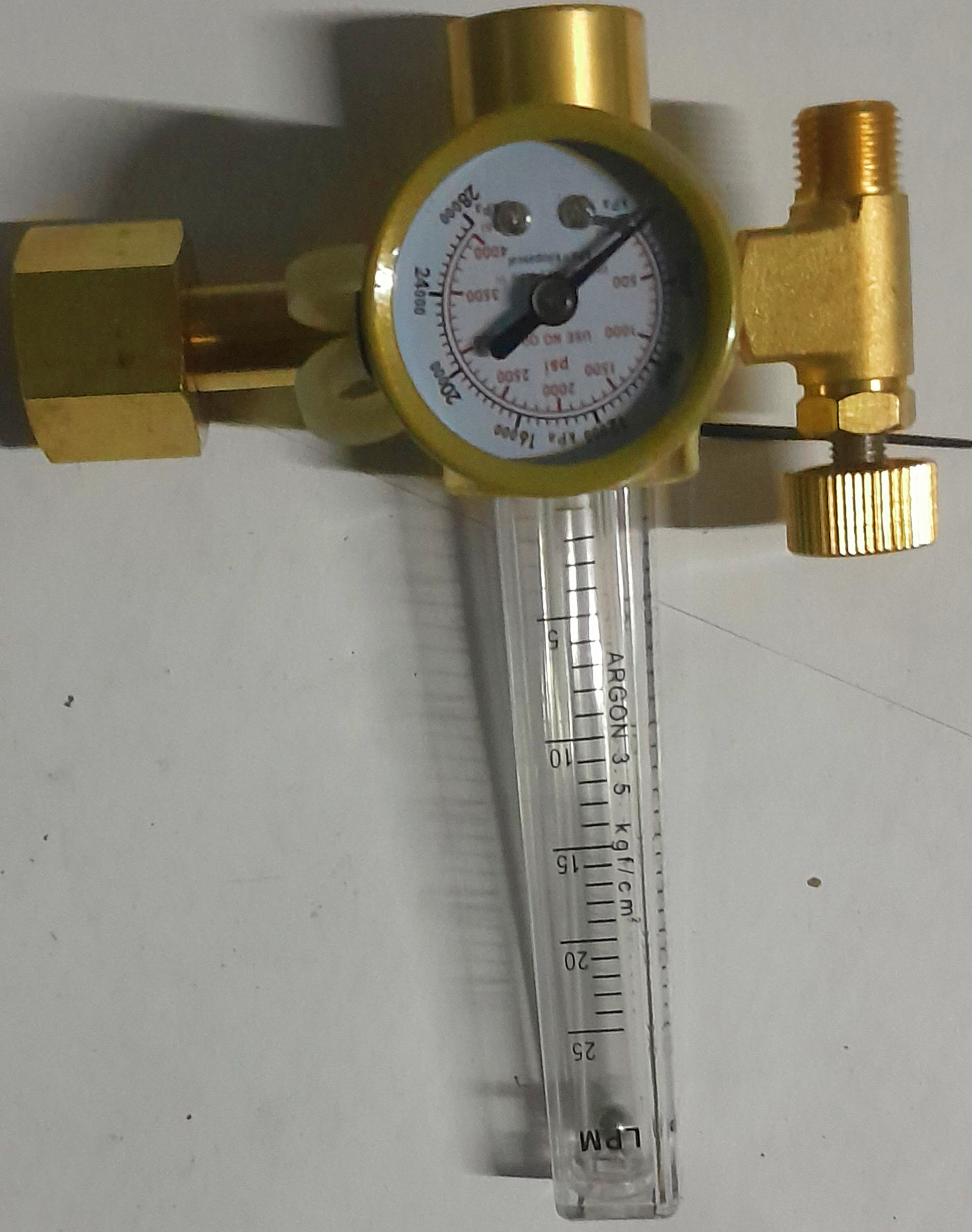

Argon Flow Meters are essential tools used in welding and industrial applications to measure and regulate the flow of argon gas. Argon is commonly used as a shielding gas in processes like TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding to protect the weld pool from contamination. Here’s a detailed description of the product:

—

Key Features:

1. Precision Measurement:

– Accurately measures the flow rate of argon gas, typically in liters per minute (LPM) or cubic feet per hour (CFH).

2. Durable Construction:

– Made from robust materials like brass or stainless steel to withstand high pressure and harsh industrial environments.

3. Easy-to-Read Scale:

– Features a clear, calibrated scale for precise flow rate adjustments.

4. Adjustable Control Valve:

– Allows users to easily regulate the flow of argon gas to suit specific welding requirements.

5. Compatibility:

– Designed to connect to standard argon gas cylinders and welding equipment.

6. Safety Features:

– Often includes a pressure relief valve or safety mechanism to prevent over-pressurization.

—

Applications:

– TIG Welding: Provides precise argon flow control for high-quality welds.

– MIG Welding: Ensures proper shielding gas flow for clean and strong welds.

– Metal Fabrication: Used in industries where argon is required for welding or cutting.

– Laboratory and Industrial Use: Regulates argon flow in specialized applications.

—

Benefits:

– Accurate Flow Control: Ensures optimal gas flow for consistent welding results.

– Durability: Built to last in demanding industrial environments.

– Ease of Use: Simple to install, adjust, and read.

– Versatility: Compatible with various welding setups and gas cylinders.

—

Safety Tips:

– Always inspect the flow meter for damage or leaks before use.

– Ensure the flow meter is compatible with your gas cylinder and welding equipment.

– Use the correct pressure settings to avoid over-pressurization.

– Store and handle argon cylinders in a safe, upright position.

– Follow manufacturer guidelines for installation and operation.

—

Argon Flow Meters are a critical component for welders and industrial professionals who rely on precise gas flow control for high-quality results. If you need further details or assistance, feel free to ask!