Description

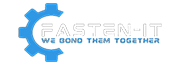

An acetylene regulator is a device used to control and regulate the flow of acetylene gas from a high-pressure cylinder to a lower, usable pressure. It is commonly used in welding, cutting, and heating applications where acetylene is combined with oxygen to produce a high-temperature flame. Here’s a detailed description of an acetylene regulator:

—

Key Features:

1. Pressure Control:

– Reduces high-pressure acetylene from a cylinder to a safe and manageable level for use.

2. Gauges:

– Typically includes two gauges:

– **Cylinder Pressure Gauge:** Displays the pressure of acetylene remaining in the cylinder.

– **Outlet Pressure Gauge:** Shows the pressure of acetylene being delivered to the torch or equipment.

3. Adjustable Outlet Pressure:

– Allows the user to adjust the outlet pressure to meet specific requirements.

4. Material:

– Made from durable materials such as brass or stainless steel to withstand high pressure and resist corrosion.

5. Safety Features:

– Includes a pressure relief valve to prevent over-pressurization and ensure safe operation.

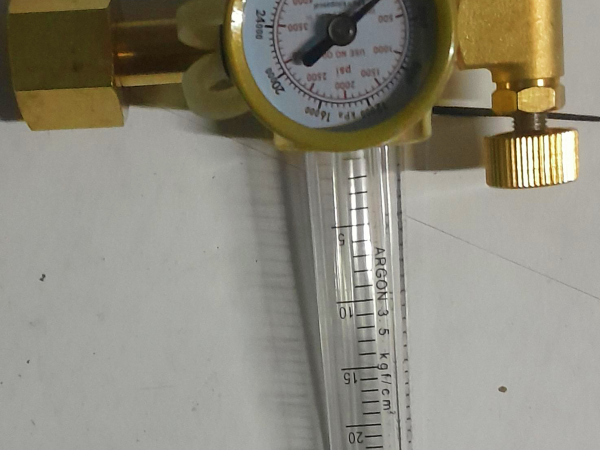

6. Connections:

– Designed to fit standard acetylene cylinders with compatible CGA (Compressed Gas Association) fittings.

—

Applications:

– Welding: Regulates acetylene flow for oxy-acetylene welding processes.

– Cutting: Used in oxy-acetylene cutting torches for metal cutting.

– Heating: Provides controlled acetylene flow for brazing, soldering, and heating applications.

– Industrial: Used in metal fabrication, repair work, and other industrial processes.

—

Benefits:

– Precision Control: Allows accurate adjustment of acetylene pressure for specific tasks.

– Safety: Built-in safety features ensure reliable and secure operation.

– Durability: Resistant to corrosion and wear, ensuring long-lasting performance.

– Versatility: Suitable for a wide range of welding, cutting, and heating applications.

—

Safety Tips:

– Always inspect the regulator for damage or leaks before use.

– Ensure the regulator is compatible with your acetylene cylinder and application.

– Use the correct pressure settings to avoid over-pressurization.

– Store and handle acetylene cylinders in a safe, upright position.

– Follow manufacturer guidelines for installation and operation.

—

An acetylene regulator is an essential tool for safely and efficiently controlling acetylene flow in welding, cutting, and heating applications. If you need further details or assistance, feel free to ask!